Phil Needham spends many hours testing and evaluating different drill/air-seeder attachments and modifications. This enables Phil to make sound seeding system recommendations to producers around the world. The John Deere 750 drill (pictured) was evaluated with most of the currently available attachments, plus more still under development. The modifications on the drill to the right included 11 different styles of firming attachments (including two different plastic seed firmers and 9 different firming wheels), plus 3 different style gauge wheels and 4 different style rear closing wheels.

John Deere Single Disc Seed Slot Characteristics

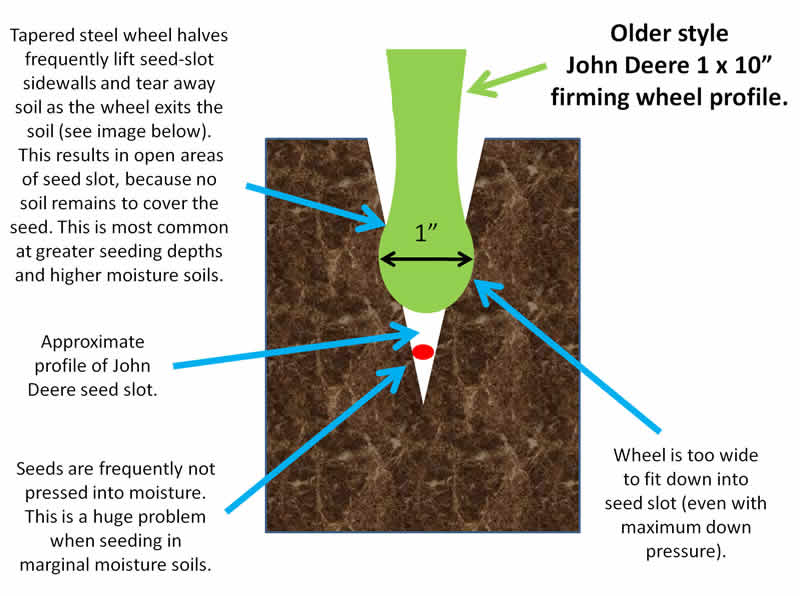

This image illustrates the John Deere single disc seeder seed slot when viewed from above. Within moist no-till conditions (and when using a new disc blade), the seed slot frequently measures between 5/8 and 3/4” of an inch in width, with a slight tapered furrow wall opposite the disc blade. As the disc blade (and boot) wear, the width of the seed slot decreases in width and the angle of the taper increases. Close inspection of the image to the right will reveal that the factory installed John Deere 1” firming wheel (which was sold until summer 2006) was too wide to fit down within the seed slot to effectively press seeds into moisture. Pressing seeds into moisture is very important, especially when trying to obtain a stand in lower moisture soil conditions.

This image illustrates the John Deere single disc seeder seed slot when viewed from the end. This image was obtained by lifting up the seed firming wheel and closing wheel with string and driving forward with the seeder engaged in the soil. Notice the profile of the seed slot within a moist silt loam soil type in a no-till system. Also notice how the seeds are loosely dropped into the bottom of the seed slot. Pushing these seeds in the base of the seed slot (we call it imprinting) is critical within low moisture conditions to create uniform emergence. Most commercial seed firming wheels on the market are too wide and the wrong shape to accomplish this task consistently across different soil types and moisture conditions.

This image illustrates some of the many concrete seed slot molds Phil Needham utilized in the wheel design process. Different soils, seeding speeds, seeding depths and moisture levels all have an influence on seed firming wheel performance and most seeding environments across the US have been tested.

Current John Deere Firming Wheels

This image illustrates both the former 1” x 10” seed firming wheel (right wheel) together with the more recent John Deere 0.8” x 9” seed firming wheel (left wheel) which was introduced during the summer of 2006. Despite the new wheel being 0.2” narrower and tapered on both sides, these improvements still don’t allow it to fit down into the seed slot in most field conditions. Increasing the firming wheel down-pressure does help to push it down into the seed slot within loose soils, but any weight transferred to the firming wheel must be subtracted from the down pressure available to the disc opener. Weight transfer is important because weight on the disc blade is frequently a factor which limits performance of the John Deere single disc seeder, especially in hard dry soils or when working with heavy residue.

Notice how the 1 x 10” John Deere firming wheel tears soil out of the sidewall as it exits the moist soil.

New Needham Ag V8 Firming Wheel

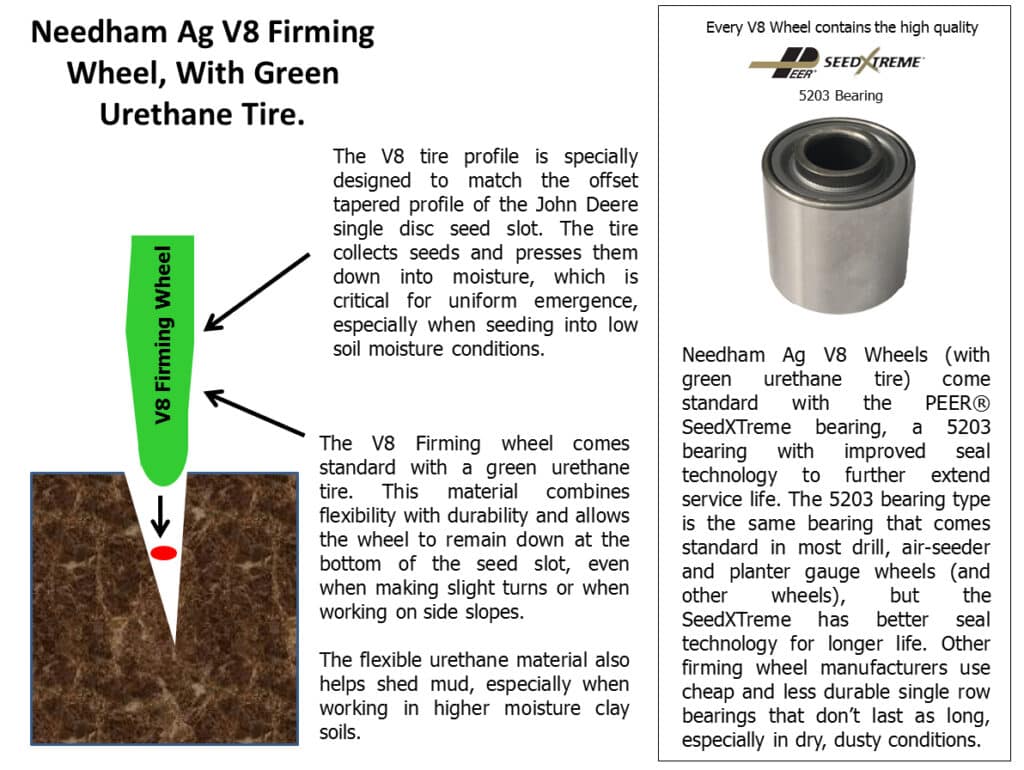

The next generation of Needham Ag V8 firming wheel was released during fall 2017. This new version retains the proven profile (the only one on the market which matches the shape of the seed slot), but it now comes with a urethane tire.

The urethane tire offers the benefits of increased durability, plus flexibility to help shed mud, especially in moist clay soils. The flexible tire is also beneficial to help keep the firming wheel down within the seed slot, especially when operating on hillsides and when making slight turns.

Needham Ag V8 Firming Wheel – Specifications

- 0.65” wide (at the outside of the tire), with tapered profile to match the seed slot.

- 10″ diameter.

- Uses button head bolts to help improve residue flow, especially in no-till conditions (see image right).

- Each V8 wheel is shipped with a longer (3.5”) Grade 8 x 5/8” low profile head bolt, nylon lock nut and washer, to mount the V8 firming wheel to the existing firming wheel arm. (A longer bolt is required, because the long-life bearing is wider than all other firming wheel bearings).