The Problem

We regularly hear from growers who plant large areas with John Deere drills or Air-Seeders, that tell us their gauge wheel axles have seized up and can’t be adjusted as seen above. This is most common in low rainfall regions where a cloud of dust often surrounds the seeder during most of the planting season and it is especially common on drills or air-seeders that don’t have adequate down pressure or ballast (or a combination of the two).

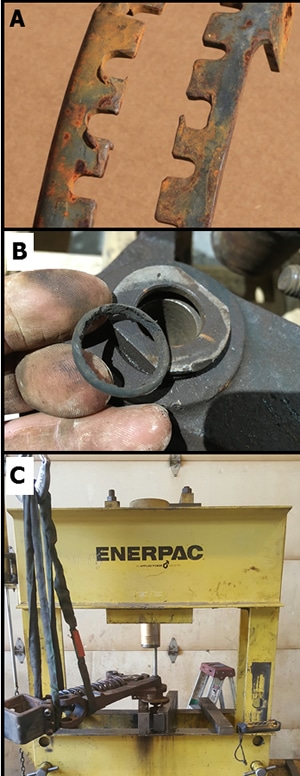

Without adequate down pressure (or ballast), the gauge wheel doesn’t remain in constant contact with the soil surface and this loss of target seeding depth causes the handle to constantly rattle within the depth adjusting cover as shown in image A. Not only does this reduce crop emergence as a result of shallow placed seeds, or seeds on top of the ground, it also causes the gauge wheel arm to constantly pivot back and forth. The constant movement wears out the O ring as shown in image B.

Once this O ring deteriorates as shown above, it lets dust into the assembly, causing it to seize up. Some clay-based greases actually made this locking up problem worse, as the dust mixes with the grease to cause a “cake-lock failure” where the gauge wheel arm seizes solid. When the gauge wheel arm can’t be moved with a large crescent wrench, hooked to where the gauge wheel mounts, the only way to free them up is to push the gauge wheel arms out of the assembly with a press as shown in image C.

Wear on cast depth arm allows gauge wheel movement

Another wearing part, especially on older or higher acre 60 and 90 series John Deere drills and air-seeders is the cast depth arm, part number AN282108 (RH) and AN282109 (LH). These wear within the jaws as illustrated right. This wear allows the gauge wheel to move up and down and change seeding depth, plus it accelerates wear within the depth adjust cover as shown.

The Solution

We have a new range of depth adjust parts to help eliminate the wearing and seizing up problems.

New Depth Adjust Axle

Key Benefits

- Heavy duty assembly replaces John Deere part numbers N282117, AA92485 and AA73951, which fit all 60 and 90 series John Deere openers.

- Dust cap is welded all around, rather than spot welded like the OEM versions. This helps keep dust and moisture entering the inside of the dust cap.

- Maintains the OEM milled area on the outside of the axle to help with lubrication along the axle.

- Includes grease zerk.

- Yellow zinc coated to minimize corrosion over time.

- Allows around 1/8” of additional adjustment of the gauge wheel towards the disc. So as the lip on the side of the gauge wheel wears away, more adjustment is available to help shim the gauge wheel against the disc to help keep mud out.

New RH and LH Spindle Assembly With Triple Lip Seal

Key Benefits

- Heavy duty spindle assembly replaces John Deere part numbers AN282118 (RH) and AN282119 (LH) on John Deere 60 and 90 series openers.

- Each spindle comes complete with high quality triple lip seal to help keep dust out of the assembly over time.

- Hex head allows to help with installation.

New Depth Arm

Key Benefits

- Our single Depth Arm can be used on the RH and LH side, so one part replaces the John Deere part numbers AN282108 (RH) and AN282109 (LH) which install on John Deere 60 and 90 series openers.

- Heavy duty steel construction for longer life.

- Works with OEM gauge wheel axle, handle and depth adjust cover.

Video

Watch the video for more information on the Needham Ag Depth Adjust Parts.